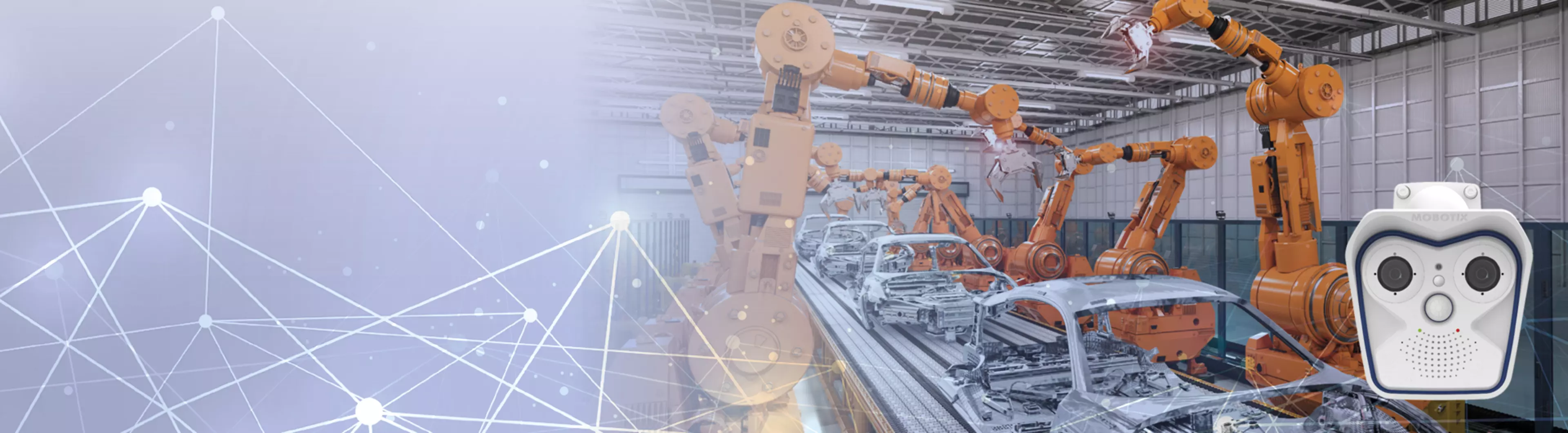

Elevate Manufacturing Efficiency and Quality with AI-Powered Visual Inspection

Quality control in manufacturing, logistics, and warehouse settings is undeniably crucial, but it doesn't have to be an uphill battle. Welcome to a game-changing solution that redefines how you ensure excellence in your processes.

In a dynamic, fast-paced environment, the human eye can only catch so much. Distractions, fatigue, and human limitations can lead to costly defects slipping through the cracks. Imagine if you could put an end to these challenges and maintain consistently impeccable standards. That's where our innovative AI-Powered Visual Inspection solution comes in.

in production and logistics environments, helping to ensure boxes are free from dirt and damage before being packed with goods for shipping. Defective boxes are automatically removed from the production line, and dirty boxes are sent for washing.

to help ensure the integrity of sheet-form and other products that require a smooth surface free from defects like scratches, tears, and glue leaks.

to guard against errors and defects in product or machine assembly such as missing, loose, or badly fitted components.

Features

Unlocking the Power of IoT Technology

Powered by cutting-edge IoT technology, our Visual Quality Inspection solution integrates smart Mobotix video cameras with FORXAI, our state-of-the-art imaging IoT platform. This dynamic duo brings the power of artificial intelligence to visual inspections, both on-site and in the cloud. Say goodbye to the unpredictability of manual inspections, and say hello to a new era of precision and reliability.

- Beyond the Surface: Scratches, cracks, poor seals, missing components — Visual Quality Inspection dives deep to catch what the naked eye can't.

- Seamless Integration: Elevate without upheaval. Visual Quality Inspection effortlessly integrates into your existing systems, enhancing automation and minimising disruption.

- Boosted Efficiency: Less downtime, fewer returns, reduced waste. Visual Quality Inspection propels your operations to peak productivity.

Instant Defect Detection

Never miss a flaw again. Our Visual Quality Inspection (VQI) employs AI-powered cameras to identify imperfections like scratches, tears, and missing components in real-time. Boost product quality and prevent costly disruptions with swift, automated alerts.

- Unrivaled Consistency: Human variability becomes a thing of the past. Visual Quality Inspection ensures every product, every process, every time is held to the same impeccable standard.

- Real-Time Alert System: Detect issues the moment they arise. Visual Quality Inspection's AI-driven analysis triggers instant alerts, empowering you to take swift action.

- Tailored to Perfection: We don't believe in a one-size-fits-all approach. Collaborating with you, we customize the algorithm to target your unique defects and anomalies.

Seamless Workflow Integration

Elevate your processes effortlessly. Visual Quality Inspection seamlessly integrates into your existing systems, enhancing automation and minimising disruptions. Stay ahead of defects, reduce waste, and achieve operational excellence without overhauling your workflow.

- Streamlined Operations: Enhance efficiency, minimise downtime, and optimise production workflows.

- Precise Defect Detection: AI-powered cameras catch anomalies the human eye might miss.

- Operational Excellence: Waste Management, ensure quality, and maintain a safer environment.

Benefits

Ensures product consistency and quality

Reduces human error risks

Saves time and labor costs

Increases production efficiency and speed

Enhances safety and compliance

Improves overall quality control